What is aluminum processing?

We process the scrap generated at your factory and return it as a raw material for your product production.

Merits of metal processing

1. Cost reduction

By returning ingots produced from your scrap, it is possible to reduce costs by reducing the utilization of new blocks, the amount of additives used, and the amount of purchased new alloys.

Please feel free to contact us regarding the adjustment of component value of return ingot.

2. Stable price not influenced by aluminum market

Buying and selling of scraps is affected by the market price of aluminum, but if you change it to metal processing, you can only recycle at a stable price that is not affected by the market price of aluminum because you only bear processing costs.

3. Realization of appropriate processing

The appropriate processing of your scrap is possible because it returns as an ingot hat can be used by your company. We can prevent environmental pollution and technology spill out due to illegal dumping of scrap.

Why choose Vietnam Fukunaga?

Ability to tie up with multiple local companies

As we have cooperated with 6 local plants in north and south Vietnam, it is possible to melt at the factory according to your scrap emissions (type, lot, shape).

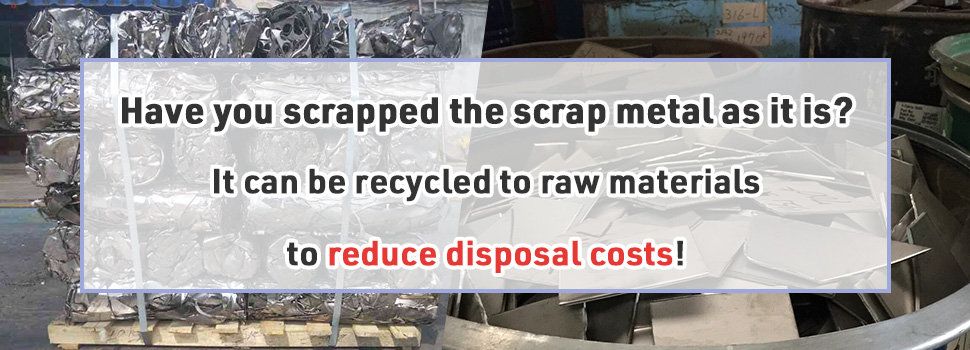

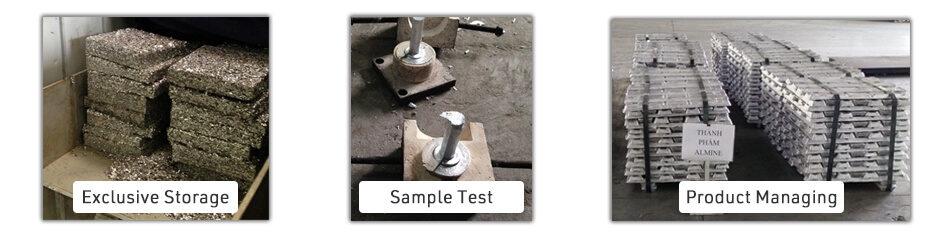

Implemented Japanese-style strict quality control under the guidance of experts

Technical guidance will be provided under the guidance of Japanese experts. Control scraps in your company's dedicated scrap storage area and prevent contamination. It is also possible to carry out sample testing the number of times agreed in advance and track lots. We will thoroughly manage the finished ingots.

Realizing transparent transactions

We prevent the faking of weighing by advance yield guarantee and third party perspective. We promise a safe transaction by the information disclosure by the report.

Transaction flow

- Implementation of your company's scrap check and dissolution test

→ Trial to determine processing cost, component value of yield ingot and yield rate. - A visit to the melting plant

→ Conducted confirmation of processing method and flow at our partner factory if necessary. - Contract signed

→ Signed this contract based on the trial results. - Scrap pick up

→ We pick up at the truck of our partner factory.

Confirmation of take-off weight by three parties (your company, our company, our company partner). - Melt processing at our partner factory

→ Bring back to the raw materials that cleared the conditions decided in advance. - Delivery

→ Sample check at your company.

If there is no problem, return the ingot and submit a report from our company.

Customer's voice

Precision parts manufacturing industry

Although the profit margin was constantly fluctuating due to fluctuations in the stock price of the materials, the metal processing made it a fixed amount of price and it contribute to business stability.

Aluminum products manufacturing industry

Various component values were required for each product specification, and each formulation had cost and effort. The metal processing has saved time and effort in component adjustment and addition of additives, and has improved work efficiency.

Automotive parts manufacturing industry

Although its value as scrap was low, it could be adopted as a raw material within its own group by re-alloying, and it was possible to introduce aluminum processing.